CNC Machining Center

Our milling machines enable a wide range of machining operations. Each of our CNC 3-axis machining centers can be additionally equipped with special workpiece clamping systems or heads, thus enabling collision-free 4-axis, 5-axis or 5-axis machining.

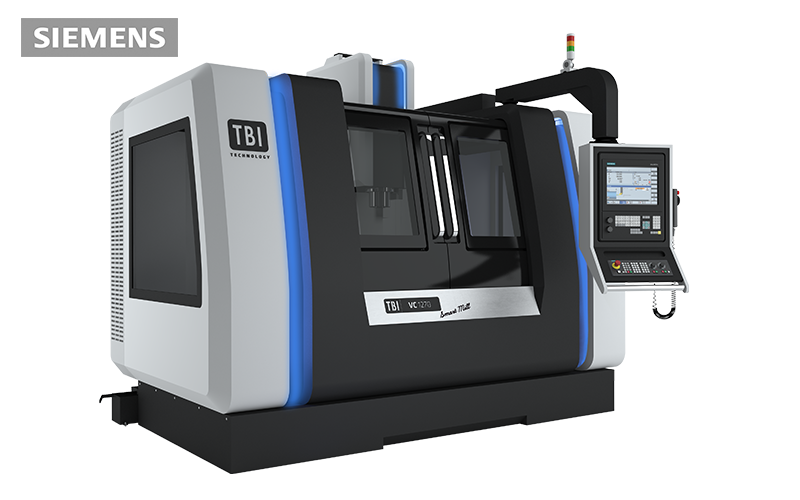

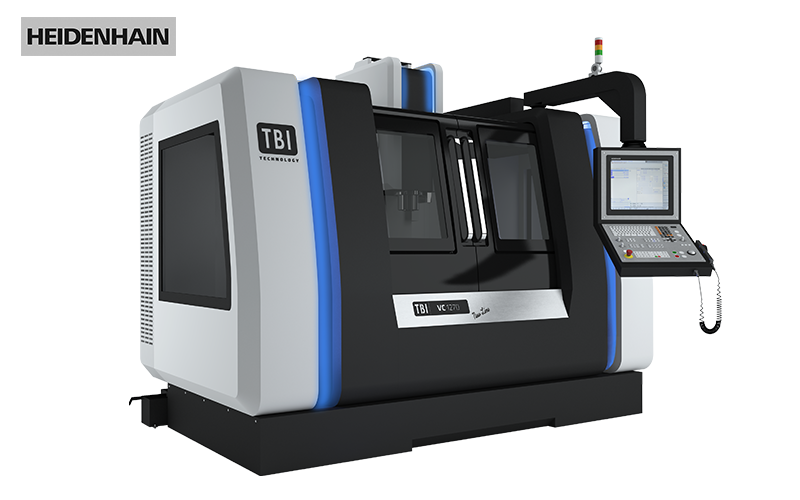

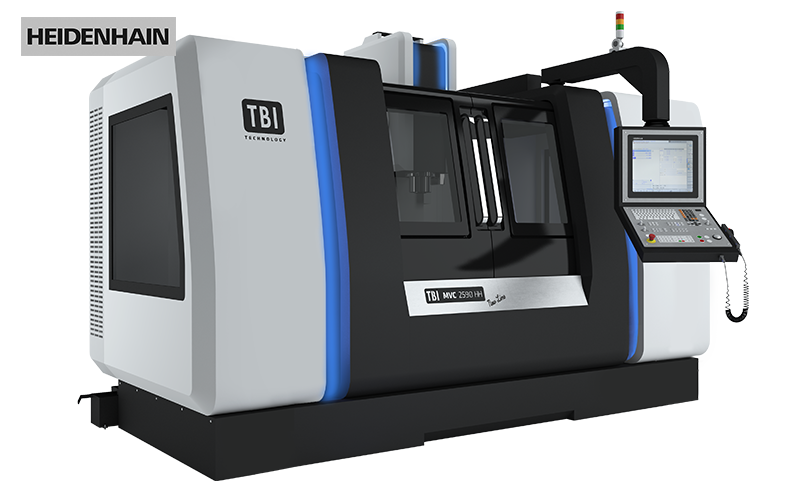

Vertical Machining Centers – Vertical Milling Machines

TBI’s range of 3-axis vertical milling machines for metalworking includes several models from which you can choose the functionality to suit your needs. For example, the small compact milling machine TBI VC 1060 has a relatively small axis and a tool magazine for 24 tools, but stands out for its high feed rate: up to 36 m/min in the X/Y/Z axes.

Horizontal Machining Center

TBI’s horizontal machining center, such as the SH 500 milling center with a 500 × 500 rotary table, has a chain magazine for 60 positions and uses a servo drive. The feed speed in the X/Y/Z axis is 30 m/min. We also offer a milling machine with a larger table 1000×1000, which is equipped with a two-arm automatic tool changer, it’s tool magazine holds 40 tools, and the travel speed is 15 to 20 m/min. Both machines have a T-slot for easy attachment of external tooling such as a machine vice, which can be found in another category of our store.

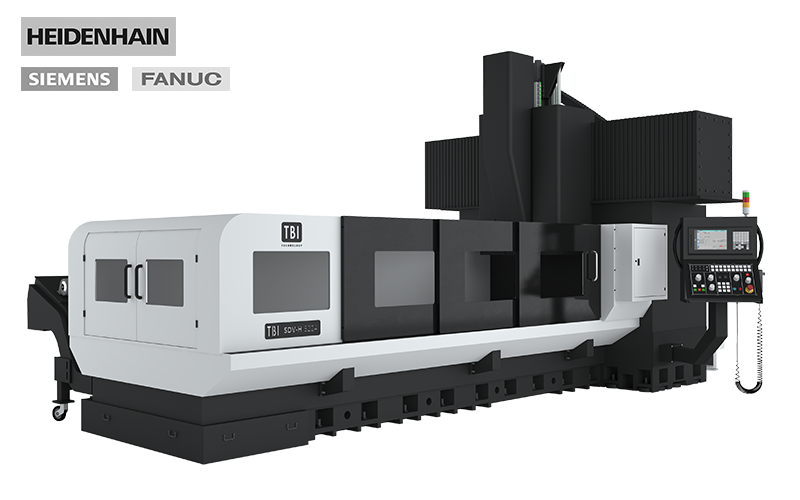

CNC Double Column Machining Center

CNC Double Column Machining Center are used for machining bulky workpieces with high weight, from 3 to 22 tons. They can process on 5 sides. TBI SDV-H 1611 model has a table with an area of 1600 x 1000 mm and a load capacity of about 3000 kg. Tool magazine with a two-arm exchanger, with the basic number of tools 24, and optionally from 32 to 40. Feed in the X/Y/Z axes from 12 to 15 m/min. or from 15 to 20 m/min.

5-axis milling machines

The TBI U5 5-axis milling machine is a CNC machine tool, which, in addition to travel in the X Y Z axes, has a table rotating in the C axis in the range of 360 degrees at a speed of 25 revolutions per minute and tilting in the B axis +40 degrees and -110 degrees with the same speed of rotation per minute as in the C axis. The magazine holds 32 (40, 60) tools. The feed rate in the main X/Y/Z axes is 36 m/min.

Avaliable models differ from each other, but they also have many common features. All TBI milling machines have a body made of cast iron, temperature stabilized spindle, quick double-arm tool changing and full protection of working space.

As you can see, we offer modern and safe devices that will improve the work in your machine park.

Zapytaj konsultanta

Zapytaj konsultanta