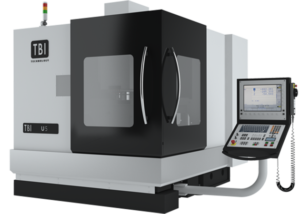

The machining of workpieces in many axes requires the use of appropriate equipment that will speed up the performed works significantly. TBI offers 5-axis machining centers, which allow machining in as many as 5 axes. See what are the most important features of offered milling machines and choose the model best suited to your needs.

TBI 5-axis machining center – the most important features

The most important feature of the U5 machining center is the possibility of machining workpieces in 5 axes simultaneously. This functionality makes the milling machine suitable for demanding machining. Simultaneous machining of a workpiece in 5 axes significantly increases the speed of work and guarantees a great final result. Each of the 5-axis milling machines has a tilting-rotating table.

It is worth mentioning that with the help of these milling machines it is possible to process not only small parts, but also bulky materials, because the maximum weight of the processed material is 4 tons.

Each 5-axis milling machine is equipped with a tool magazine, which allows for very fast replacement of tools. The size of the tool magazine depends on the specific model, and some offer the possibility of choosing one of the available variants.

5-axis machining centers – extensive standard equipment

The U5-series machining centers, like other TBI products, are distinguished by their extensive standard equipment. This allows for high quality and precision machining in all planes, which directly affects the quality of the machined parts. Each U5 machining center is equipped with a direct-drive spindle with temperature stabilization, which guarantees perfect surface finish.

We would like to invite you to have a look at the full offer of 5-axis milling machines available at TBI. All of them are designed in such a way as to make 5-axis milling machining easier and more efficient.

It is also worth choosing them due to extensive additional equipment and easy access to spare parts, thanks to which, in case of failure, machine downtime is reduced to a minimum. Browse through the available models, check their technical parameters and then order the 5-axis machining center that is best suited to your needs.

Zapytaj konsultanta

Zapytaj konsultanta