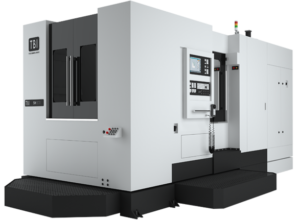

Machining large and complex 3D models requires the proper equipment. The horizontal machining centers of the SH series are perfectly suited for this task. Check which models of horizontal milling machines are available in this category and choose the horizontal machining center that best suits your needs.

Horizontal machining center – many standard features

We care about our customers, that’s why TBI machining centers always have extensive equipment as standard. Thanks to this, you can use many functionalities offered by other manufacturers only at an extra charge, which significantly increases the attractiveness of our offer.

Each TBI horizontal machining center is equipped with a pallet exchanger, temperature stabilisation of the spindle, cooled ball screws and a quick double-arm tool changer. A workspace guard makes using the milling machine safe, and easy access to the workspace and loading area makes the machine easy to operate.

Operating comfort is also enhanced by the use of a lower chip flushing system, integrated chip conveyor and handwheel. All these features are available in the basic machine equipment, which is the best proof that TBI horizontal milling machines take care of machine users in every aspect.

Horizontal machining center – many different models

There are various models of horizontal machining centers available at TBI. They differ, among other things, in the work range, including the length of the table travel in each of the 2 axes and the headstock, the size of the table and its load. Important differences also concern the spindle parameters – the type of its drive, power, number of rotations or a taper, as well as a tool magazine. The last refers not only to its size – the number of tools that can be accommodated in it, but also to the method of their replacement. Available models use a chain or two-arm automatic exchange system.

When you are choosing a horizontal machining center for yourself, it is worth paying special attention to the parameters listed above and match it to the materials to be processed. The offer is so wide that everyone is sure to find a model perfectly suited to the type of machining they plan to do. However, regardless of the model you choose, you can be sure that it will be a top quality machining center, designed for comfort and wide application possibilities. Have a look through the available models, and then choose the one that best fits your needs.

Zapytaj konsultanta

Zapytaj konsultanta