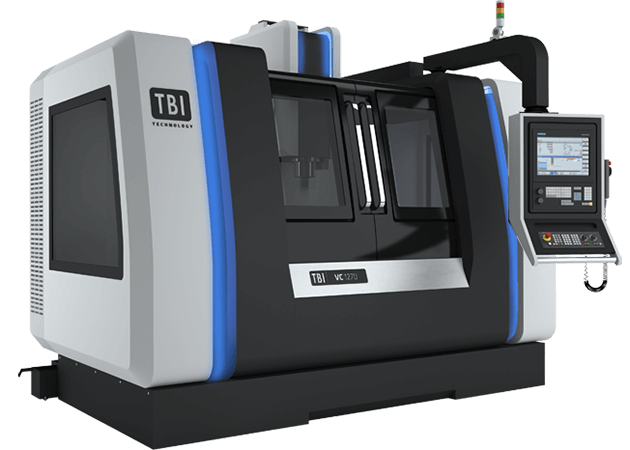

1. what is the waiting time for the TBI VC 1270 milling machine

TBI VC 1270 Smart mill vertical machining centers are produced in a continuous cycle and we maintain a minimum stock for them in Poland. The standard waiting time for a machine from the warehouse is a maximum of 4 weeks. On the other hand, if the CNC machine tool is manufactured from scratch – the waiting time is 4 to 6 months. More about what the delivery date of a CNC machine tool depends on in the content of our

BLOG

.

2. what is the accuracy of the TBI VC 1270 Smart Mill vertical machining center

For the new TBI VC 1270 machine, our guaranteed positioning accuracy is ?0.003, and positioning repeatability is ? 0.002. This parameter is measured with a two-way passage over the entire length of the axle passage, i.e. 1200 mm. About the positioning of the machine, about the standards used in this area we write in the

ARTICLE

.

3. how to arm a new CNC machine tool?

As part of the TBI brand , we have a separate tool brand, TBI Tools. Its offer is designedto make the process of CNC implementation easier for the customer at the stage of machine purchase. When purchasing a TBI Technology machine, we offer tool starter packages that guarantee a quick start of production and selection of the optimal metalworking technology.

4 Spindle cooling - applications and benefits

All TBI brand machine tools have spindle cooling as standard. Learn in detail about its use and benefits in

ARTICLE

.

5. how to prepare for the delivery of the TBI VC 1270 Smart Mill Vertical Machining Center

In order to speed up delivery, it’s a good idea to prepare for it properly beforehand. What does it mean? The customer always receives a machine size guide so that he can arrange his hall space for a new CNC machine tool. There are all the necessary transportation and installation data for a specific machine model.

6 Why choose to finance a metalworking machine?

In order to remain competitive in the market and increase the quality of their services, more and more companies are choosing to purchase a new CNC machine tool. However, it is often the case that not all customers want to commit a larger sum of money. In this case, they choose to take advantage of available forms of financing, particularly leasing. In that case, they commit funds only for their own contribution; the leasing company finances the rest.

7. What type of lease to choose?

More favorable for tax purposes is the operating lease, the initial payment, the full lease payment and the expenses incurred on the leased object are included in the tax deductible expenses. The condition is that the contract is concluded for at least 40% of the depreciation period for the asset and that there is a limitation in the determination of the final redemption value. VAT is added to each lease installment.

In the case of a finance lease, the entrepreneur becomes the owner of the CNC machine and makes monthly depreciation deductions, only the interest and all expenses incurred are charged to expenses. There are no restrictions on the contract term or residual value, while VAT is paid on the full value of the machine along with the first installment.

8. what is the duration of the lease?

The standard financing period for the purchase of a CNC machine is 3 to 5 years, but it is possible to extend financing up to 7 years.

Shortening an operating lease is more complicated. If it occurs before 40% of the normative depreciation period has elapsed, the regulations oblige the leasing company to sell the leased asset, at the market value confirmed by an appraiser’s valuation or at the outstanding value, whichever is higher.

9. will the new company get lease financing?

There is no clear answer. Certainly obtaining financing through a CNC machine supplier can make the process easier. Significance will be given to the amount of the declared initial fee (minimum 20%), the assets of the company and the owner, the possibility of guaranteeing with private assets by the lessee or representative, the prospects of the company (experience of managers, contracts concluded, the amount of turnover.

Zapytaj konsultanta

Zapytaj konsultanta

Download the specification card

Download the specification card